Quality assurance for recipes: testing, evaluating, documenting

The example implementation described below shows how you can achieve complete traceability and meet modern quality standards by linking recipes, projects, and samples—from development to testing.

Key advantages & concepts

Central data management

- Each recipe is linked to a project.

- The project collects all recipe-related data and links measured values, specifications, and clients/customers centrally.

- All relevant information can be found in one place—from recipe development to final testing.

- Complete transparency is possible for all project participants.

Data-based evaluation and optimization

- We prepare your data for statistical evaluations and trend analyses.

- Historical data is accessible and usable for continuous improvement.

- Different recipe variants can be compared with each other.

Automatic quality comparison and quality assurance

- Measured values and specifications are recorded via the samples (tests) and automatically compared.

- Deviations are immediately apparent. The LDB immediately displays deviations (red) and confirms values (green).

- Automatic target/actual comparison saves time and reduces errors.

- Standardized testing processes can be applied to all recipes.

- Comparability is ensured across time and variants.

Flexible variant management

- Multiple recipes, recipe variants, and samples can be assigned to a project. You can develop and test multiple recipe variants in parallel.

- Different formulations can be compared directly with each other—perfect for recipe development and optimization.

- The optimal recipe can be identified quickly.

- You maintain an overview of all development stages, can make informed, data-driven decisions, and systematically improve your recipes.

Traceable documentation and compliance

- Complete traceability of all tests and results.

- All changes are documented in the audit trail.

- With structured data storage, you can easily meet compliance requirements, be ready for audits, certifications, and customer inquiries, and build trust.

- The continuous documentation chain facilitates subsequent analyses.

Example implementation

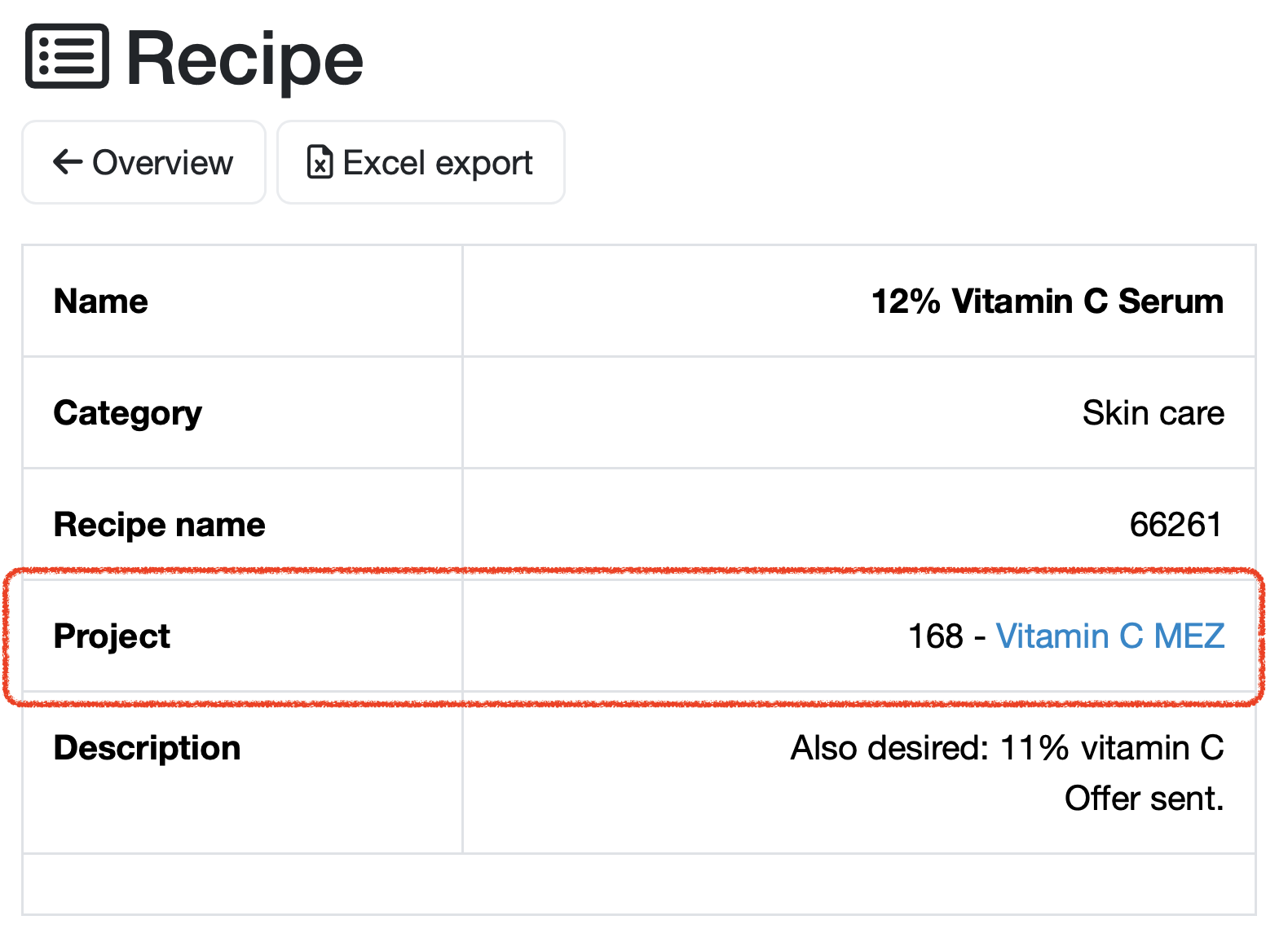

1. Create recipe and link project

When creating a new recipe or variant, the associated project is selected and linked to the recipe.

The linked project is displayed in the project field of the recipe form (e.g., 168 - Vitamin C MEZ).

Once linked, all project data are available.

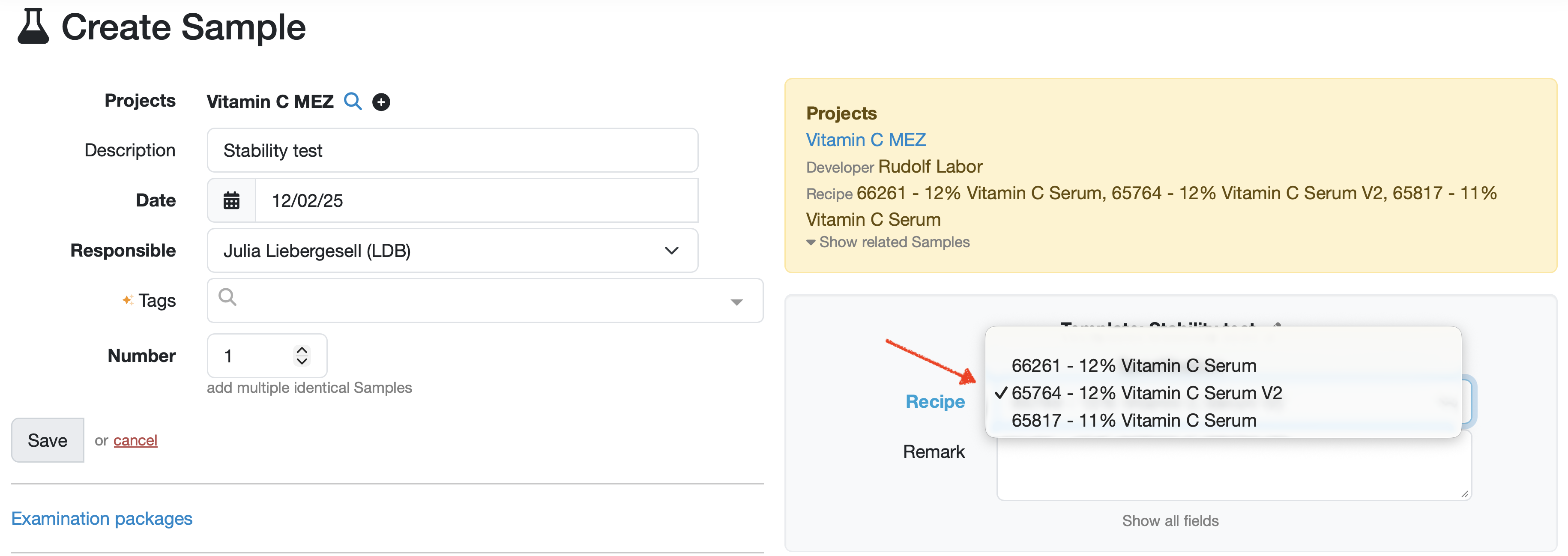

2. Create sample and assign recipe

To record measured values for the recipe, create a sample for the project.

Select the desired recipe using the selection field for the sample.

Select the desired recipe from the drop-down menu, e.g., 66261 - 12% Vitamin C Serum V2.

The recipe is then assigned to the sample and the sample is automatically linked to the project.

The project link ensures that only suitable recipes are available for selection, thus ruling out any confusion.

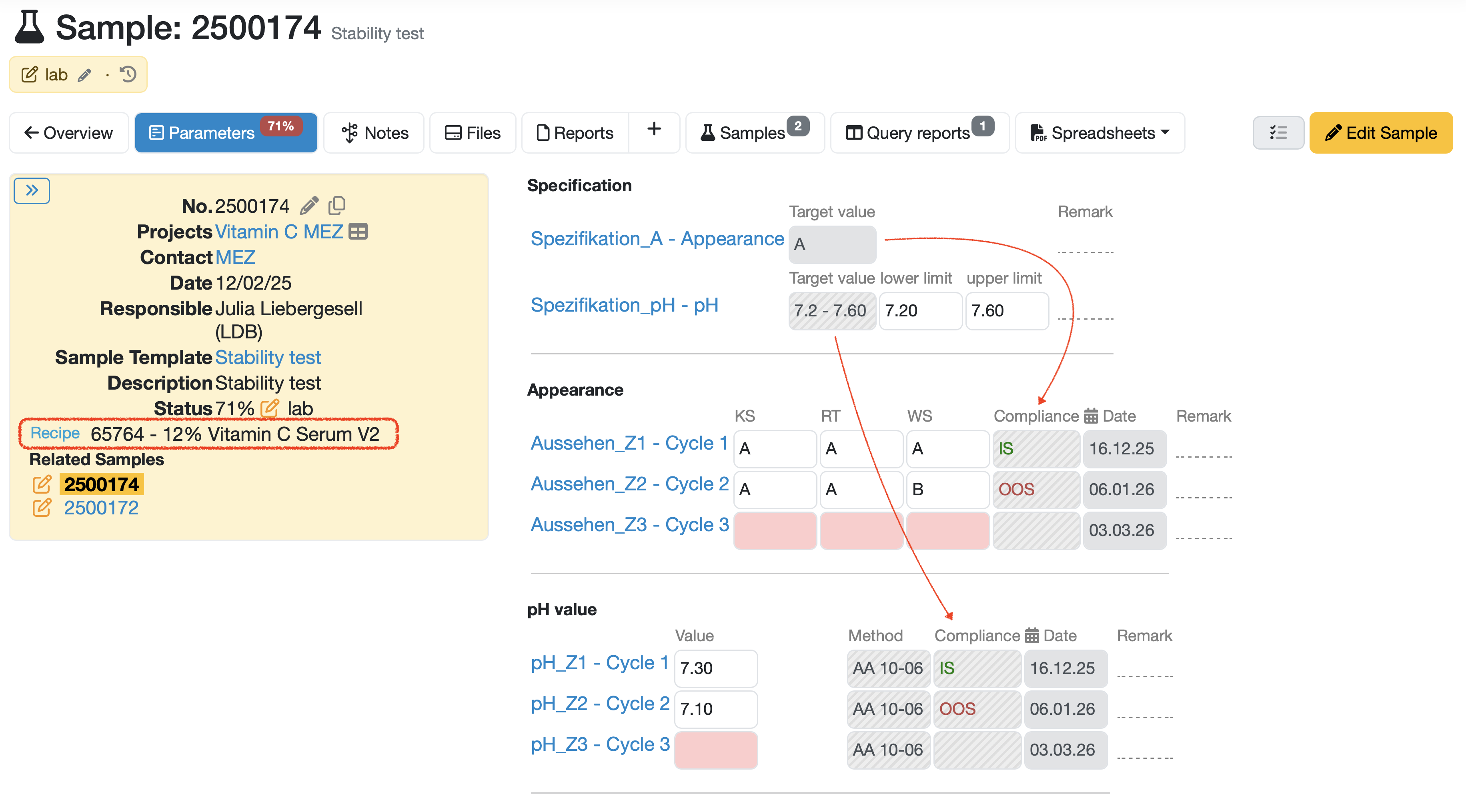

3. Record measured values and compare them with specifications

All measured values are now entered in the sample and automatically compared with the defined specifications.

Green markings indicate that the values are OK (within the specification).

Red markings indicate that deviations have been detected (outside the specification).

(This example uses one-time specifications that are recorded as parameters. For frequently used specifications, it is recommended to create them in the specification management or as a specification sample may be more advisable.)

All measured values for this test can be traced back to the respective recipe and are available for statistical evaluations, continuous improvements, and trend analyses.

Related topics: Manage recipes

Last change: 02/11/26

General information

- Main menu

- Dashboard

- Backup / Data protection

- Version number of the LDB

- Supported browsers

- Activation of SSO

- Print labels

- Automatic LDB validations

- Create/Edit/Delete Categories

- Status management

- SMTP Configuration

- Konfiguration SMTP via OAuth 2.0

- IT requirements for the use of the Labordatenbank

- Add Dashboard Widgets

- Evaluation criteria for suppliers

- Edit evaluation criteria for suppliers

- Restore Deleted Records

- Manage PDF Templates

- Email informations

- Filter management - Search filter and column filter

- Edit Filters - Search Filters and Column Filters

- Hours per week

- Annual overview

- Hours per day

- Vacation days

- Edit hour

- Manage Weekly Hours

- Manage materials

- Onlineorder detailview

- Manage orders

- Edit orders

- Edit process key figures

- Create process key figures

- Manage 8D-Reports

- Process management view editing

- Edit processes

- Manage Projects

- Edit projects

- Edit planned order

- Edit planned samples

- Create/edit/delete station

- Tag management

Employees

- Manage employees

- Add/edit/archive employee

- Archive employees

- Reactivate archived employees

- Manage employee groups

- Edit employee group

- Create task

- Audit Trail: traceable documentation of all work

- Access rights

- Edit Accessright

- Tracking working hours

- Labordatenbank Login

- Change password

- activate Multi-Factor-Authentification (MFA) with TOTP

- activate a Security Key for the MFA

- Activation of Passkey

- Install TOTP App

- Import employees (introduction phase)

PDF templates

- Create/edit PDF templates

- Create design elements

- Design elements Setting options

- Integrate report tables into design template

- Design element for the reason for reissuing test reports

- PDF template for sample labels

Recipes

- Manage recipes

- Create/edit recipe

- Recipe detail view and ingredients

- Quality assurance for recipes: testing, evaluating, documenting

Reports

- Create report

- Inserting Images and File Attachments into a Report

- Sign reports

- Request signature

- Reissue of signed reports

- Send reports by e-mail or post

- Protect emails from spam filters

- Verify authenticity of reports and certificates

- Certificate

- Manage signatures

- Create / edit / delete a signature

Report table editor

- Create/edit/delete a report table

- Create / Edit reporttable column

- Creating a parameter table with target values

- Create sample table

- Create table with open structure

- Order of the report tables

- Fonts and character set for PDF reports

- Report tables overview

- Create checklist with report table editor

- Measurement repetitions value selection

Interfaces

- Import Interfaces Overview

- AI Extension for Import Interfaces

- Edit Attributes in Import Mapping

- Import results from measuring instruments

- Create CSV measurement data import interface

- Import measurement data

- Import of samples

- Mode for measured value import

- Automatic FTP/SFTP Import

- Test SFTP/FTP Connection

- Testing the HTTPS Import Interface

- Transformation code for importing other data formats

- Practical example: Import GC/MS measurement values to your LIMS system

- Practical example: Import Biomerieux Vitek antibiogram into LIMS

- Connect Thermo Fisher Chromeleon to LIMS

- Connect PCR to LIMS with plate assignment

- LIMS connection to DEMIS reporting for pathogen detection

- Tips for import interfaces

- Imort pictures in parameters

- Connection of Essentim data loggers

- SHAPTH - Drinking water database

Kompetenzen

AI functions

- Activate/deactivate AI functions

- AI Explorer

- Query Explorer

- AI Import: Automatically assign external calibration certificates

Introductory phase

- Labordatenbank introduction checklist

- Labordatenbank data structure

- Implementing the QM-Database

- Import parameters (Introduction phase)

- Import sample master data (Introduction phase)

- Benefits of the LDB Cloud

- configurable master data fields in the LDB

- Transfer files securely to the LDB

Query reports

- Create query reports using a template

- SQL Basic Course

- SQL JOINs

- SQL Basics

- Create / Edit query reports

- Parameter columns

- Variables in query reports

- Export data from query reports

- Link Evaluations

- Query report tables (SQL table and SQL bar chart)

- Save and Display MySQL Backup Locally

- Link evaluations with import interface

Orders

- Create Order

- Add an order using a template

- Equipment GPS location

- Add samples with an order template

- Add on-site inspection

- Delete order

- Scanning and sending documents to the LDB with QR

- Typical configurations

- Create order templates

- Create orders using templates

- Defining order access rights

- Order schedule

Samples

- Manage samples

- Add samples

- Add multiple identical samples

- Enter values

- Edit samples as a group

- Sample search

- Sample sorting rules

- Statistical evaluations

- Save sample search as filter

- Show results table

- Column filter for results table

- Create filters specific to employee groups

- Automatic creation of analysis orders for external contracting

- Create analysis plan for samples

- Automatic Sample Notifications

- Delete samples

- Map pooled samples in LIMS

- Sample Tracking with QR Code (Scanning at Stations)

Templates

Customers

- E-mail templates for reports and invoices

- Create customer

- Add / Edit / Delete contact persons at customers

- Merging duplicate customers

- Search customers

- Forward emails to the LDB

- Import customers ( introduction phase)

- Delete Customer

Client zone (optional)

- Customerzone

- Activating the Customer Zone

- Create Online Analysis Order

- Sampling with online analysis order

- Hide parameter columns in customer portal

- Provide files in the customer zone

Assets

Offers

- Create offer

- Add prices and price items

- Appendix with Terms and Conditions and Service Catalog

- Send Offer

Invoices

- Create Invoice

- Sending Invoices

- The English translation for "Teilzahlungen bei einer Rechnung erfassen

- Manage price list

- Exporting invoices

- Import billing items (Introduction phase)

- Create revenue centers for prices

- Activate X-invoice / E-invoice for Germany

- Create Collective Invoices

- Cancel invoice

- QR code for online banking on invoices

- Suggest billing items

Parameters

- Parameter management

- Add/Edit/Delete Parameter

- Create/edit/delete parameter group

- Daily Parameter List: What has to be done in the laboratory

- Parameter usage statistics

- Labeling of subcontracting and accreditation

- Parameter data types

- portray proficiency tests

- Manage examination packages

- Create/Edit examination packages

Calculating with parameters

- Deposit formulas with parameters

- Calculating with number sequences

- Calculation of dry matter and annealing loss

- Calculating with Date/Time Information

- Example: Weighing in and weighing out

- Example: Calculation of annealing loss with validity check

- Example: Determination of Chemical Oxygen Demand

- Example: Determination of TVC - aerobic mesophilic total viable count

- Bsp.: Drinkingwater-Legionella since March 2023 (German Regulation)

Webservices

- LDB Webservices

- Provide data as web services for external systems

- Send data to an external web service

- Send data to the Labordatenbank

- Example: Send eTermin to the LDB

- Example: JSON file for creating samples

Transformationscode

- General structure of a transformation code

- Transformation code for evaluations

- Export transformation code

- Webservice Response Handler

- Import transformation code

Test plans / limit values / specifications

- Create test plan / limit value table / specification

- Add specification limits / reference ranges

- Measurement value evaluation based on reference range values

- Detect and filter reference range deviations

- Parameter-specific text modules according to limit tables

Documents control

- Create a New Document

- Create new version

- Validate document

- Release Document

- Request read confirmation

- Import documents (Introduction phase)

- Change the document creator afterwards

- Delete documents

- Documents: Confirm validity check

Material

- Functions of Material Management

- Create/edit/delete material

- Linking materials with parameters

- Reorder Materials Online

- Management of chemicals

- Manage/Create/Edit/Delete Batches

- Use batch samples

Questions and answers

- IT requirements

- Where can I find the current version number of the _LABORDATENBANK__?

- How can I calculate the average from five measured values?

- Where do you enter titles like Dr/Prof/Dipl. etc.?

- How can I change the order of parameters in the packages?

- Querious: Delete archived reports

- Download files in the Edge browser instead of opening them directly

- Transfer the status of the production system to the test system

Equipment

- Test Equipment Management

- Test equipment detailed view

- Add/edit/delete Test Equipment

- Import test equipment (introduction phase)

- Create control charts

- Import control values from test equipment

- Print labels for test equipment

- Forward emails to test equipment

- Booking Test Equipment

- Test Equipment Calendar

Trainings

- TrainingSchedule: Document Training Sessions, Demonstrate Competencies

- Add/edit/delete training

- Import Trainings (Introduction phase)

8D-report

Others

Supplier evaluation

File management

- Add Files (to Samples, Customers, Orders)

- Add Files (Test Equipment, Material, Batches, Specifications)

- File Management

- Search data

Processes